Introduction with helpful tips on how to set up your CNC machine. How do you even begin, what do you need? What will happen if you mess it up? What is the difference between wood and metal? There are different types of wood engraving machine and metal carving machines. These machines use CNC technologies. Here are some interesting facts about CNC machines.

What is CNC

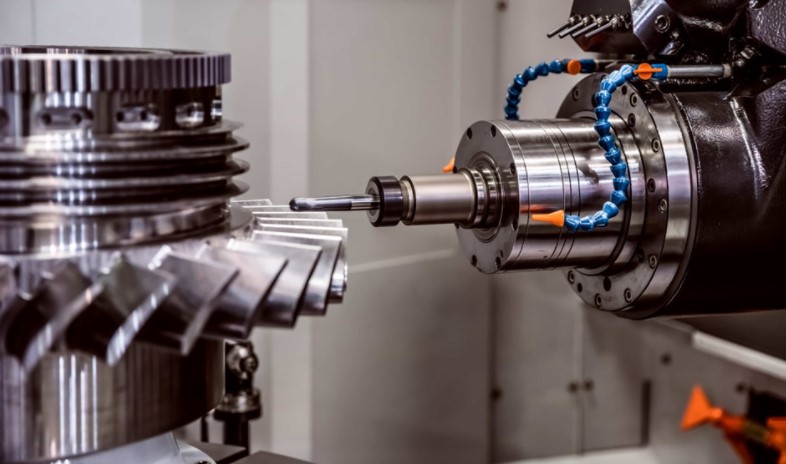

CNC stands for Computer Numerical Control. A CNC machine programs itself by moving along a digital model that represents a complete path with rotating axes, cutting to the line, or stopping on command at increments of less than one millimeter. Machines like these can be cut into wood, metal, concrete, and plaster without manual breakage like other machines tend to produce. CNC wood router machines are used in the manufacturing process, enabling the highest precision.

CNC stands for Computer Numerical Control. A CNC machine programs itself by moving along a digital model that represents a complete path with rotating axes, cutting to the line, or stopping on command at increments of less than one millimeter. Machines like these can be cut into wood, metal, concrete, and plaster without manual breakage like other machines tend to produce. CNC wood router machines are used in the manufacturing process, enabling the highest precision.

Uses of CNC

In the machine shop, CNC is basically a computer-controlled system that guides cutting tools in order to work on different materials that may be very difficult by hand. As with any new technology, the first use was for simple everyday jobs like making calibration blocks for machine tools. Nowadays, more complex tasks are accomplished through this process like building and cutting aerospace components for jet fighter fuselages. Grain mills, water pumps, and paper-making machines are just a few examples of machines that are CNC machined. These machines help grind materials more quickly to offer more efficient systems for the production of different goods. CNC is one of many computer-controlled machine tools used in nearly every industry today.

How Does it Work

If you’ve ever looked at your computer and wondered how it makes those complicated shapes, then deep cleaning a garage, cutting plastic sheeting, etchings or working with wood as thin as a sheet of paper – then there’s a better chance than you think that’s what your machine is doing. CNC stands for Computer Numerical Control, which is a computer-controlled machine that can move in any given direction. This includes the ability to carve inscriptions, cut or mill material, engrave a pattern or picture and create three-dimensional objects like sculptures.

Types of CNC Machines

CNC (Computer Numerical Control) is a process that designs, codes, and programs, controls the equipment to create a finished product. Depending on size and usage, there are three types of machines: milling presses; lathes; and notching or routing type machines.

Safety Measures

In order to ensure the safety of your employees and customers, many of these companies take precautionary measures in hopes of ensuring the success of their CNC machinery. Many companies have placed caution tape on machines when operational because unexpected uncontrolled movements can lead to accidents that would result in expensive damages.

Conclusion

Whether you are trying to make a key or a sign for your business, becoming familiar with the process of dragging and cutting all over your design is imperative in the world of machining. We have all seen them in the homes and workplaces: large 3D printers, lasers, lathes, milling machines, and all other kinds of industrial cutting tools.